Products

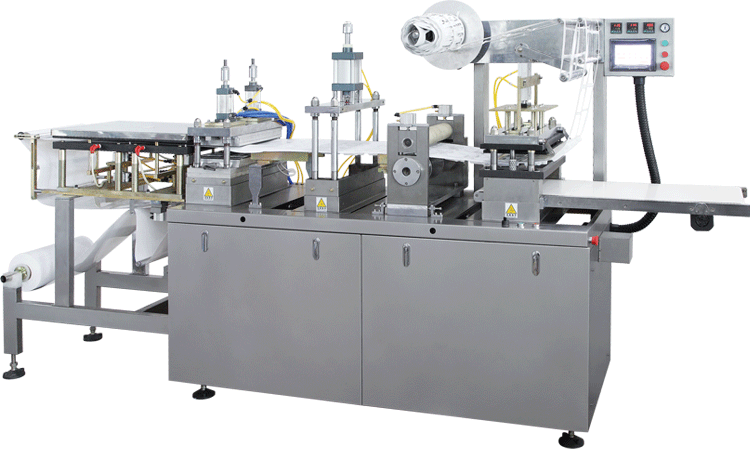

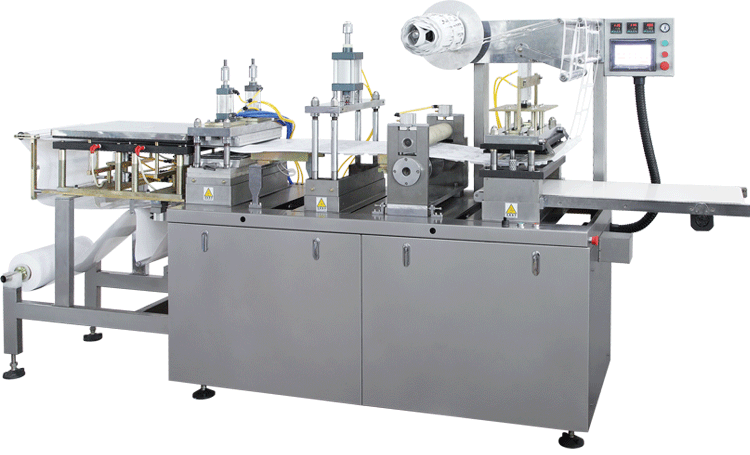

Usage:

It is suitable to foam BOPS. HIPS. PS. PVC. PET and other plastic sheet roll, which can produce various of lids for plastic/paper cups, mini soup spoon, trays for medicine and etc.

Major Construction Features

1, The achievement of GMP/QS double standard p clean production, improve product hygiene and safety, meanwhile,resolve cross-contamination.

2, Roll Film Loading, Forming, Hole Punching, Transmitting, Roll Film Winding Six-Station Synchronous Production. Manipulator Feeder, Compact Structure & Stable Performance, Easy Operations.

3, Journey is Adjustable, easy to change mold, suitable for different specifications.

4, The operation is controlled by PLC with PC Circult Control Board for Touch Screen

Note: Special specification and configuration of products can be designed according to customers’ demand.

Main Technical Parameters:

|

Used Material |

HIPS,PS,PVC,PET,no PP |

|

Cutting Frequency |

8-32times/min |

|

Travel Range |

50-160mm |

|

Max.Forming Depth |

52mm |

|

Max.Forming Area |

400X160mm |

|

Mould Cooling |

Tap Water of Circulating Water 60L/S |

|

Total Power |

10kw |

|

Air Consumptions |

>0.5M/Min |

|

Air pressure |

0.5-0.7Mpa |

|

Overall Dimensions |

3500 x 1000 x 1700mm |

|

Weight(kg) |

1400kg |

|

Machine packing details |

3050 x 1050 x 1900mm |

|

Packing weight(kg) |

1500kg |

| * Subject : | |

| * Message : | |

| * Contact : | |

| * Email : | |

| CompanyName : | |

| * Phone : | |

| * Fax : | |

| * Address : | |