Products

Machine is mainly suitable for filling capping and labeling various oil products, liquid products, paste lotion products, sauce products, etc. Good universality, high stability, durability. It is widely used in various fields

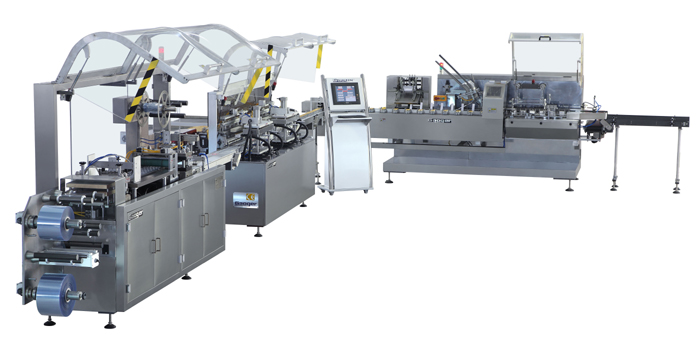

Introduction and Scope of Bottle Filling Capping and Labeling Machine

It is mainly suitable for filling capping and labeling various oil products, liquid products, paste lotion products, sauce products, etc. Good universality, high stability, durability.

Principle Features of Bottle Filling Capping and Labeling Machine

1. wide applicability: widely filling range, capping and labeling;

- Filling viscous liquids,better mobility of liquid products, like lube oil, edible oil, sunflower oil, butter, sauce, etc.

- Capping: screw various types of caps, widely application

- Labeling: it is not only available for square bottles, flat bottles (full bottle state and other bottle s type) to label on the (plane) leaflet / corner side, but also can achieve the round bottle to locate leaflets / double pieces’ attachment feature.

2. Unique sub-material structure to ensure reliable and effective sub material when used with production line

3. Not only stand-alone use, but also used in conjunction with the production line

4. Filling:

- No bottle no filling, no leakage phenomenon.

- High filling precision and power enough

- Three line of defense: anti-drip aspects

- Stability: stable and durable

- Client feedback : durable equipment, not easy to damage

working procedure:

Bottles turntable----Bottle liquid filling & capping ----bottle labeling machine

|

Bottle Turntable |

|

|

Application: |

Round bottle that can stand on the table steady |

|

Turntable |

Φ900mm (Customized) |

|

transfer capability : |

Comply with the washing machine |

|

power supply: |

220V 50HZ or 380V(Customized) |

|

power: |

1.0KW |

|

Outside dimension: |

950×1100×950mm(L×W×H) |

|

Liquid filling and Capping Machine |

|

|

Capacity |

50-60 bottles/min |

|

Filling station |

4-8 filling head stations (Customized) |

|

Capping Head |

One(Customized) |

|

Applied For |

1-200ml (Customized) |

|

Filling Tolerance |

±1% |

|

qualified Cap putting : |

≥99% |

|

qualified Capping: |

≥99% |

|

peed control: |

by Inverter |

|

power supply: |

380V 50Hz or 220V (Customized) |

|

Total power |

2KW |

|

Outside dimension: |

3000×800×1550mm |

|

Vertical labeling machine |

|

|

Labeling range: |

bottle Diameter from Ф20mm~Ф100mm |

|

Label range: |

height :20~90mm, length: 20~270mm |

|

Yield capacity: |

60-80 pcs/min[depend on the bottle size and label size] |

|

Labeling tolerance: |

±1mm[no consider the tolerance of the bottle and label] |

|

Label roller: |

Inner Diameter Ф76mm , max. outer Diameter Ф300mm |

|

Power supply: |

220V 50Hz |

|

Power : |

500W |

|

Outside dimension: |

1820 x1100 x 1500 (L ×W ×H) |

|

Machine weight: |

240Kg |

| * Subject : | |

| * Message : | |

| * Contact : | |

| * Email : | |

| CompanyName : | |

| * Phone : | |

| * Fax : | |

| * Address : | |